The key to the production of Aluminium Solar Panel Frame is the mould. The above mold design scheme can be selected according to different conditions and requirements, and can also be used as a reference when other profiles use double-hole molds....

The key to the production of Aluminium Solar Panel Frame is the mould. The above mold design scheme can be selected according to different conditions and requirements, and can also be used as a reference when other profiles use double-hole molds. Using the production mode of double-hole large machine, the key is to optimize the design parameters of the mold. Only with a reasonable mold design can we obtain profiles with good surface quality and high mechanical properties, so as to achieve the goals of improving production efficiency and reducing costs. meet market requirements.

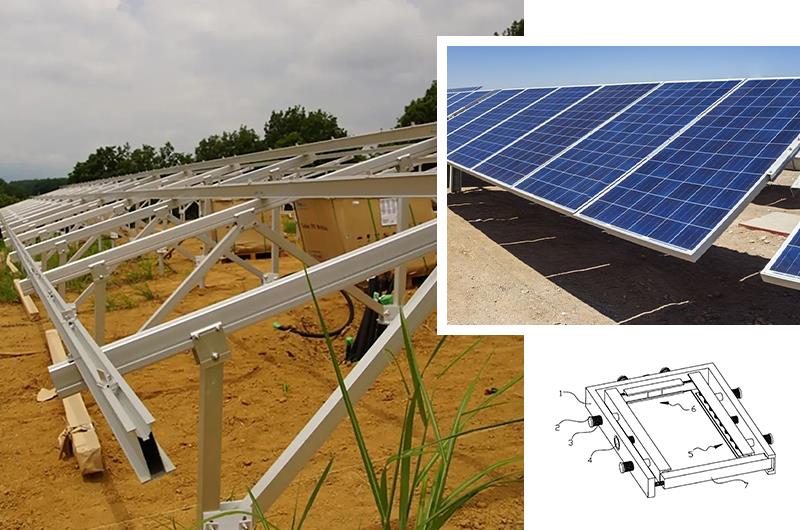

Because aluminum alloys have good corrosion resistance and weldability, they are widely used in various fields, especially those requiring

In industrial structural parts with certain strength and corrosion resistance. As a renewable and environmentally friendly energy source, photovoltaic solar power generation has ushered in a golden period of development in recent years, driven by the international market and relevant domestic policies. my country has become the world's largest producer of solar cells/modules, while Aluminium Solar Panel Frame occupies the position of the world's largest producer and supplier, and the market demand for Aluminium Solar Panel Frame is quite large. However, at present, manufacturers produce this type of material by using the traditional single-hole extrusion method of small machines. The disadvantage of this is that, on the one hand, in order to cope with large-scale production orders, there are many machines and molds to be used, and the extrusion efficiency is low; on the other hand, when small machines are used for production, the extrusion coefficient is low and the degree of deformation is insufficient , the mechanical properties that can be achieved are low, and the potential of extrusion deformation is not fully exerted. Some manufacturers have also tried to use large machines for production in order to obtain higher mechanical properties, but using single-hole extrusion production, the degree of deformation is too large, and it is easy to squeeze and even die prematurely.

Therefore, using a double-hole or multi-hole die for extrusion production on a large machine can not only meet the extrusion coefficient required for deformation, but also improve the extrusion production efficiency.