Description of aluminum led strip light housingAluminum alloy has excellent thermal conductivity, and it has become an industry consensus to use aluminum alloy as led strip light housing. In addition to using high thermal conductivity shell materials, designing enough effective heat dissipation area and reducing the thermal resistance from the led chip to the shell surface in contact with the air will affect the quality of led strip light....

Description of aluminum led strip light housing

Aluminum alloy has excellent thermal conductivity, and it has become an industry consensus to use aluminum alloy as led strip light housing. In addition to using high thermal conductivity shell materials, designing enough effective heat dissipation area and reducing the thermal resistance from the led chip to the shell surface in contact with the air will affect the quality of led strip light.

Aluminum alloy housing is an important component of led strip light, which involves lamp heat dissipation, waterproof performance, cost structure, lamp weight, etc. At present, aluminum alloy housing accounts for about 3-40% of the cost of led strip lights.

Features of aluminum led strip light housing

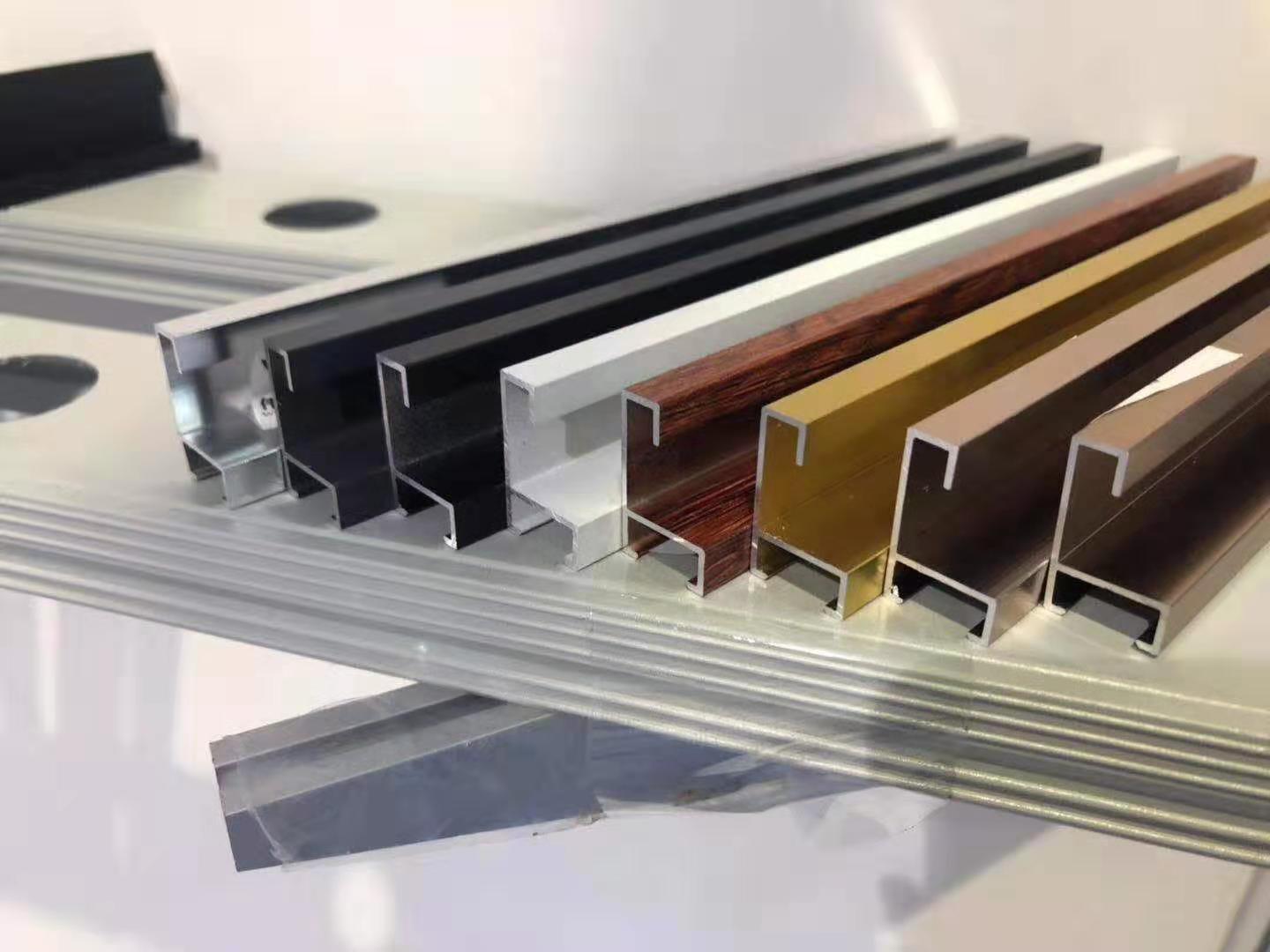

The aluminum alloy housing of the led strip light has good heat dissipation performance, waterproof performance, novel appearance, embedded structure with adjustable light angle, and wide applicability.

The aluminum alloy housing of the led strip light includes a heat sink, a tray, a cover plate, a backing plate and a lens, the heat sink is an aluminum alloy heat sink, and a ring of heat dissipation fins is arranged on the inner wall of the aluminum alloy heat sink. It is embedded above the aluminum alloy heat sink, the backing plate is annular, the backing plate is arranged on the tray, the edge of the cover plate extends downward to form a folded edge, and the cover plate is connected to the aluminum alloy through its folded edge. The outer edge of the top of the alloy heat sink is clamped, the lens is arranged in the middle of the cover plate, and the edge of the lens is clamped between the backing plate and the cover plate.

The outer diameter of the aluminum alloy heat sink is 50-300mm, and the height of the aluminum alloy heat sink is 50-600mm.

The cooling fins include chimney-type cooling fins and open cooling fins.

The tray, cover plate and backing plate are all made of aluminum alloy.

Advantages of aluminum led strip light housing

The new heat sink is an aluminum alloy heat sink, which adopts the chimney effect to dissipate heat, and the effective heat dissipation area reaches 90-140 square centimeters / watt. thermal resistance. The main structure of the lamp and the heat dissipation structure are combined into one, which greatly reduces the weight of the lamp, which is convenient for cost reduction and easy installation. Its manufacturing mold is also relatively simplified. The embedded structure with adjustable light angle and cylindrical shape make the lamp suitable for various lighting occasions such as outdoor, industrial and mining, venues, etc. It has good performance, novel appearance, light weight, low cost and wide application.